Introduction

The appareil respiratoire isolant (ARI), or self-contained breathing apparatus, is a critical piece of safety equipment designed to provide breathable air in environments where the atmosphere may be hazardous, oxygen-deficient, or contaminated. From firefighting to industrial maintenance, and from emergency rescue to hazardous material handling, this device plays a life-saving role by isolating the user’s respiratory system from surrounding air. In high-risk situations where toxic gases, smoke, dust, or chemicals threaten life, an ARI can be the difference between survival and tragedy. Knowing how these devices function, their types, and their proper usage is essential for anyone working in dangerous environments.

What is an Appareil Respiratoire Isolant?

An appareil respiratoire isolant is a self-contained unit that carries its own supply of breathing air, eliminating the need to depend on surrounding atmospheric conditions. Unlike filter-based respirators that purify existing air, the ARI delivers air from a compressed cylinder or a closed-circuit oxygen system. This makes it indispensable in areas with unknown air quality, confined spaces, or locations with zero oxygen.

Its design ensures that no contaminated air can enter the mask, creating a sealed and protected breathing environment. The ARI is also used in military, maritime, and underground rescue operations where toxic exposure is highly probable.

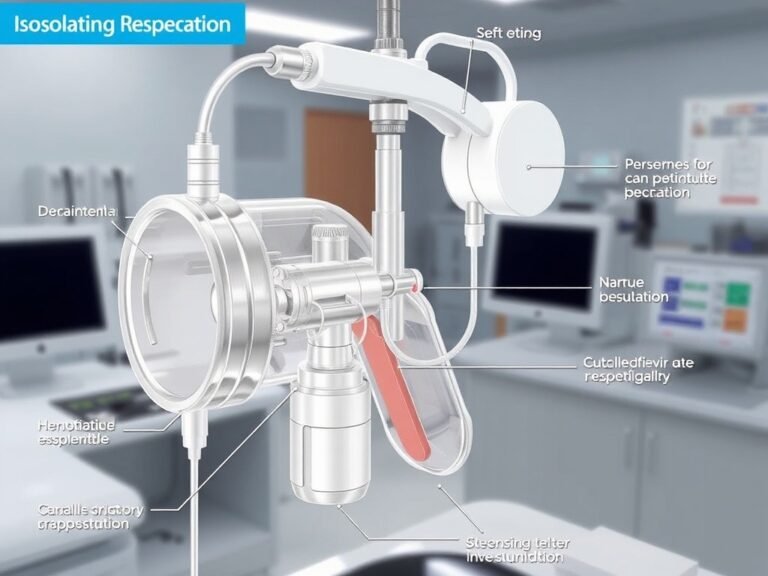

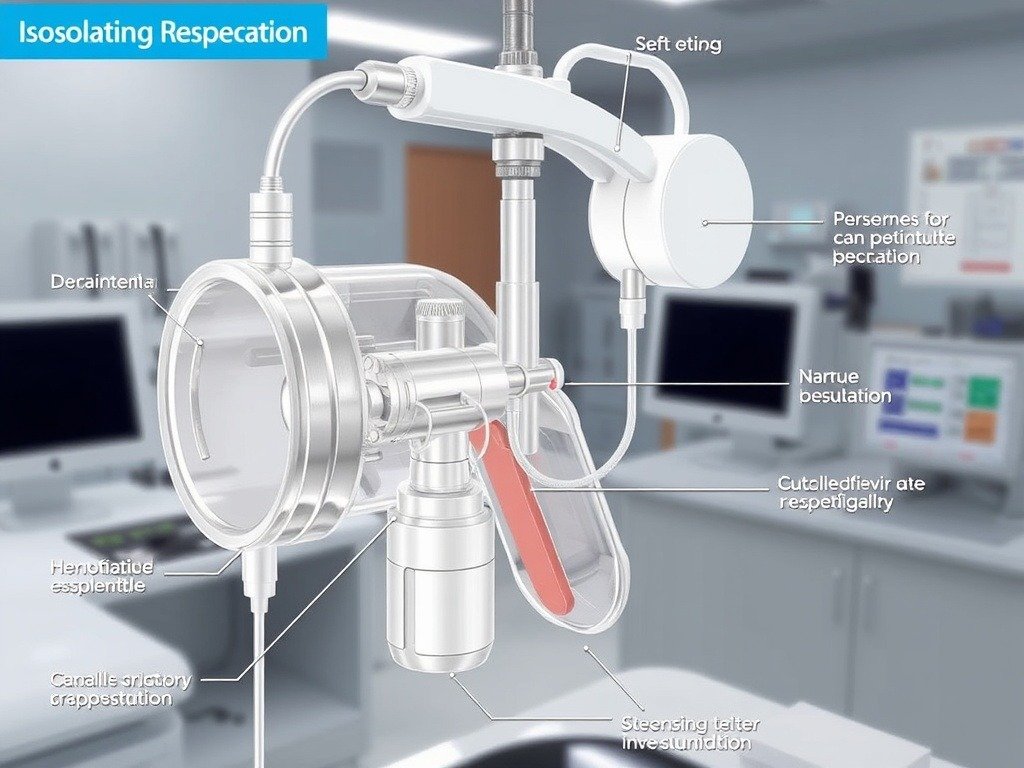

The Key Components of an ARI

The ARI consists of several integrated components that work together to ensure safe breathing.

Key elements include:

- Face Mask (Full Facepiece) – Provides a tight seal and clear vision.

- Air Cylinder or Oxygen Tank – Stores breathable air or oxygen.

- Pressure Regulator – Controls air delivery to maintain a safe breathing pressure.

- Harness and Straps – Allows secure and comfortable wearing.

- Warning Devices – Audible alarms for low air supply.

Each component undergoes rigorous testing to meet safety standards and guarantee performance under extreme conditions.

Types of Appareil Respiratoire Isolant

There are two main types of ARI, each suited to different applications and duration requirements.

| Type | Description | Common Usage |

| Open-Circuit ARI | Supplies air from a cylinder and releases exhaled air into the atmosphere. | Firefighting, industrial maintenance, rescue operations. |

| Closed-Circuit ARI | Recirculates exhaled air after scrubbing CO₂ and replenishing oxygen. | Mines, submarine rescue, long-duration hazardous work. |

The choice between open or closed circuit depends on working time, weight considerations, and the environment’s oxygen and contamination levels.

When Should an ARI Be Used?

An ARI must be worn whenever the surrounding atmosphere is unsafe for breathing. Common situations include:

- Fire and Smoke Environments – High levels of carbon monoxide and particulates.

- Chemical Spills or Leaks – Presence of toxic vapors or gases.

- Confined Spaces – Risk of oxygen depletion.

- Industrial Shutdowns – Areas with potential ammonia, chlorine, or solvent fumes.

- Disaster Response – Post-earthquake, flood, or building collapse scenarios with dust and contaminants.

Failure to use proper respiratory isolation in such cases can result in serious injury or death.

Advantages of Using an Appareil Respiratoire Isolant

The ARI offers unique safety benefits compared to other breathing protection methods:

- Complete independence from ambient air conditions.

- High filtration and airtight sealing.

- Immediate protection against sudden air quality changes.

- Compatibility with additional safety gear like helmets or hazmat suits.

- Longer operational time with closed-circuit designs.

These advantages make the ARI the top choice for professionals in life-threatening environments.

Limitations and Challenges

While ARIs are highly effective, they also have limitations that must be understood for safe operation:

- Weight and Bulkiness – Can cause fatigue during prolonged use.

- Limited Air Supply – Requires careful monitoring to avoid depletion.

- Training Requirements – Users must be trained to handle emergencies such as mask leaks or equipment failure.

- Maintenance Costs – Regular inspections and servicing are mandatory.

Ignoring these factors can compromise both safety and performance.

Safety Precautions Before Using an ARI

Before wearing an appareil respiratoire isolant, the user should follow strict safety checks:

- Inspect the face mask for cracks or dirt.

- Ensure the air cylinder is fully charged.

- Test the regulator and alarms.

- Adjust straps for a comfortable yet airtight fit.

- Verify communication systems if operating in a team.

These steps prevent dangerous malfunctions during critical operations.

Proper Donning and Doffing Procedure

The correct way to put on and remove an ARI can mean the difference between safe operation and exposure.

Donning Steps:

- Place the harness on shoulders and secure straps.

- Fit the mask tightly and check the seal.

- Open the air valve and test airflow.

Doffing Steps:

- Move to a safe, breathable area.

- Close the air valve.

- Remove the mask and release straps carefully.

Training Requirements for ARI Operators

Operators must undergo certified training to understand:

- Equipment function and limitations.

- Emergency troubleshooting techniques.

- Safe work practices in hazardous environments.

- Team communication and rescue protocols.

- Physical fitness to handle the added weight.

Practical drills and simulations are essential to build real-life readiness.

Maintenance and Inspection Schedule

An ARI’s reliability depends on regular inspection and servicing.

Maintenance guidelines include:

- Daily visual inspection before each use.

- Weekly pressure and alarm checks.

- Monthly in-depth testing of valves and regulators.

- Annual servicing by authorized technicians.

- Immediate replacement of damaged components.

Failing to maintain an ARI can lead to catastrophic failures during use.

Common Problems and Troubleshooting

Even the best ARIs can face operational issues such as:

- Air Leaks – Caused by faulty seals or damaged hoses.

- Fogging in Mask – Can reduce visibility; anti-fog coatings help.

- Low Pressure Alarm Malfunctions – Requires urgent technical inspection.

- Breathing Resistance – Often due to clogged filters or regulator issues.

Quick recognition and corrective action are vital to avoid accidents.

Real-Life Applications and Case Studies

The ARI has been proven in countless real-life scenarios. For example, during industrial ammonia leaks, trained workers using ARIs successfully evacuated affected zones without injuries. Firefighters entering burning high-rises depend entirely on ARIs to survive toxic smoke. In mining rescues, closed-circuit ARIs have allowed trapped workers to breathe for several hours until rescue teams arrive.

Regulatory Standards and Certifications

In Europe, ARIs must meet EN 137 standards for firefighter breathing apparatus and other EU safety directives. Internationally, NFPA 1981 in the USA and ISO 23269 for marine use define performance, durability, and safety criteria. These certifications ensure that only high-quality, tested devices reach the market.

Conclusion: Why ARIs Are Non-Negotiable in Hazardous Work

The appareil respiratoire isolant is not just equipment—it’s a lifeline. In professions where air quality cannot be trusted, this device ensures survival by providing a sealed, controlled breathing environment. Workers must be trained, equipment must be maintained, and strict usage protocols must be followed. Safety is not negotiable, and the ARI remains one of the most vital tools in hazardous industries.

FAQs

Q1: How long can an appareil respiratoire isolant last in operation?

Depending on the type, open-circuit ARIs typically last 30–60 minutes, while closed-circuit units can provide air for up to 4 hours.

Q2: Can an ARI be used underwater?

No, ARIs are designed for land-based hazardous environments. For underwater breathing, specialized SCUBA equipment is required.

Q3: What is the difference between an ARI and a filter mask?

An ARI supplies its own air source, while a filter mask cleans ambient air. ARIs are used when the surrounding air is unsafe or lacks oxygen.